Vogtle Unit 1 & 2 Digital Turbine Controls

Selected project examples

Project Overview:

Client: Southern Company

Location: Plant Vogtle Unit 1

Project Duration: 4/27/15 - 4/16/17

Project Value: $15MM

Contract Method: Target Price

Total Man-hours: 242,036

Project Scope

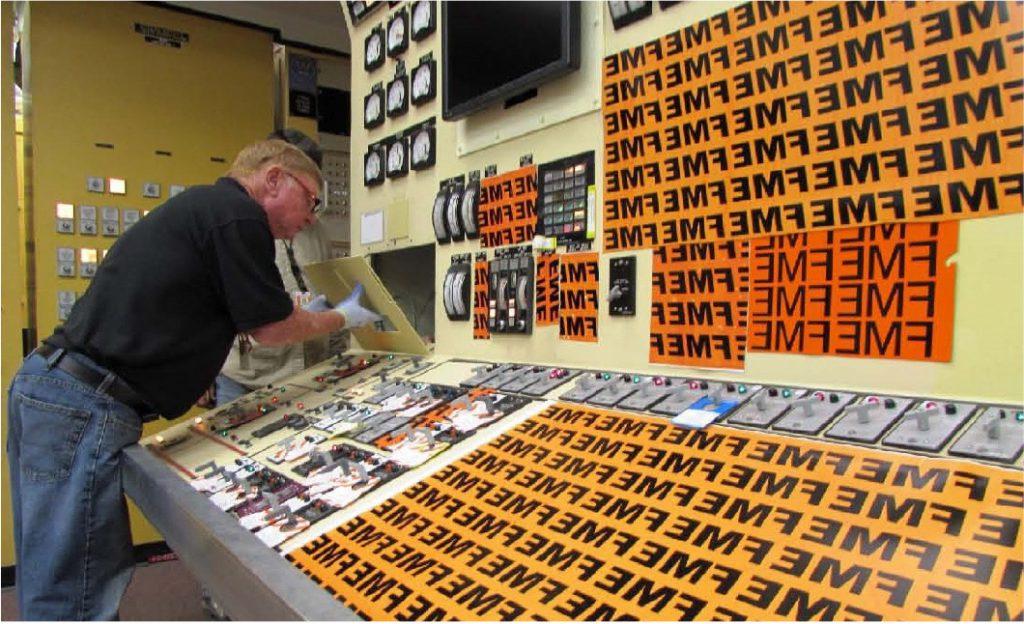

The purpose of the Main Turbine and Feed Pump controls upgrade is to improve equipment reliability associated with the turbine control system due to obsolescence of the existing equipment. Increased reliability will be realized through removal of the General Electric (GE) Mark II control system and installation of a new GE Mark VIe digital control system. Along with providing all of the existing functionalities, the project will minimize single point vulnerabilities associated with the system. Optional scope included in the plan will improve the Predictive Maintenance (PdM) program capabilities for this system and increase the reliability of several associated systems.

Project Description

The upgrade in controls for the main turbine and steam generator feed pump turbine is one of the biggest design changes in Southern Company’s history. Williams managed the overall project execution which included:

- 8600 ft. of conduit run

- 32 miles of cable pulled

- 9632 terminations, determinations, and spare cables for duration of

the project - 2 new transformers, 1 UPS – 1 battery rack and enclosure for the PEECC building

- 1800 ft. of 3/8” ss tubing

- 54 new pressure transmitters installed

- 2 trip manifold assembles for SGFP’s

- 1 trip manifold assembly for main turbine

- New valve positioners for A-B-C-D MSR’s

- Main panel and bushing flow stator cooler upgrades

- EHC tubing and pump modifications

- Lube oil control modifications

- Installation of the plant electronic electrical control cabinet in the

PEECC building - TMA platforms

- 302 scaffolds built & removed

Challenges

- Performing work while the units were online.

- Engineering design (by others) was not going to meet the timeline to implement in one outage, which drove implementation over two outages.

Project Highlights

- Creatively managed this project to do as much work online, while understanding key items that needed to occur during first outage

which were too risky to do online. - The project was successfully completed with all cable connections, transmitters and positioners in the right locations and syncing up.

- Completed work during final implementation within schedule and at the Target Price.

- Safety performance superior.